Everything about VFD (variable speed) constant pressure pump inverter

42 FAQs about VFD (variable speed) constant pressure pump inverter

1. What is VFD / VSD Constant Pressure Booster Pump Inverter?

2. Why do we need VFD / VSD Constant Pressure Booster Pump Inverter?

3. What is the difference between VFD and VSD?

4. What benefits VFD / VSD Constant Pressure Booster Pump Inverter can contribute to improve peoples’ life?

5. What are the 10 Tips to choose a good VFD / VSD Constant Pressure Booster Pump Inverter?

6. What are the 4 major benefits of using VFD / VSD Constant Pressure Booster Pump Inverter?

7. How does VFD / VSD Constant Pressure Booster Pump Inverter save energy?

8. How does VFD / VSD Constant Pressure Booster Pump Inverter provide Constant water pressure?

9. How does VFD / VSD Inverter Constant Pressure Booster Pump Inverter reduce pump operating noise?

10. How does VFD / VSD Constant Pressure Booster Pump Inverter protect water pump?

11. How can VFD / VSD Constant Pressure Booster Pump Inverter enhance water pump performance?

12. How can it be easier to assemble a VFD / VSD Inverter Constant Pressure Booster Pump system?

13. How can VFD / VSD Inverter Constant Pressure Booster Pump system be more compact and space-saving?

14. How to install VFD / VSD Inverter Constant Pressure Booster Pump?

15. How to do maintenance and service for VFD / VSD Constant Pressure Booster Pump Inverter?

16. What are the 8 major protections for water pump a good VFD / VSD Constant Pressure Booster Pump Inverter can do?

17. Why dry running protection is important for VFD / VSD Constant Pressure Booster Pump Inverter?

18. Why over and low voltage protection is important for VFD / VSD Constant Pressure Booster Pump Inverter?

19. Why over current protection is important for VFD / VSD Constant Pressure Booster Pump Inverter?

20. Why excess temperature protection is important for VFD / VSD Constant Pressure Booster Pump Inverter?

21. Why anti-freezing protection is important for VFD / VSD Constant Pressure Booster Pump Inverter?

22. Why locked rotor protection function is important for VFD / VSD Constant Pressure Booster Pump Inverter?

23. Why leakage warning function is important for VFD / VSD Constant Pressure Booster Pump Inverter?

24. What information should be shown on the panel of VFD / VSD Constant Pressure Booster Pump Inverter?

25. What are the key parts to assemble VFD / VSD Inverter Constant Pressure Booster Pump system?

26. What does a VFD / VSD inverter do for Constant Pressure Booster Pump?

27. What does a pressure sensor do for VFD / VSD Inverter Constant Pressure Booster Pump?

28. What does the check valve do for VFD / VSD Inverter Constant Pressure Booster Pump?

29. What does pressure tank do for VFD / VSD Inverter Constant Pressure Booster Pump?

30. Why most of the VFD / VSD Inverter Constant Pressure Booster Pumps are expensive?

31. How many types of VFD / VSD Constant Pressure Booster Pump Inverter are there in the market?

32. What is an All-In-One & In-line VFD / VSD Constant Pressure Booster Pump Inverter?

33. What are the advantages of All-In-One & In-Line VFD / VSD Constant Pressure Booster Pump Inverter?

34. How easy it is to assemble All-In-One & In-Line VFD / VSD Constant Pressure Booster Pump Inverter with a water pump?

35. What does flow switch do for VFD / VSD Inverter Constant Pressure Booster Pump?

36. What does union pipe connectors do for VFD / VSD Inverter Constant Pressure Booster Pump?

37. What types of water pump can work with All-In-One & In-Line VFD / VSD Constant Pressure Booster Pump Inverter?

38. What mistakes do people make when choosing VFD / VSD Constant Pressure Booster Pump Inverter?

39. What mistakes do people make when install VFD / VSD Inverter Constant Pressure Booster Pump?

40. What are the 10 things to avoid when selecting a VFD / VSD Inverter Constant Pressure Booster Pump?

41. What are the shocking truths of lousy VFD / VSD Inverter Constant Pressure Booster Pump?

42. Why not many people use VFD / VSD Inverter Constant Pressure Booster Pump?

1. What is VFD / VSD Constant Pressure Booster Pump Inverter?

A variable frequency drive (VFD) / variable speed drive (VSD) Inverter Constant Pressure Booster Pump Manager is used to adjust pressure or flow to the actual demand. It controls the frequency of the electrical power supplied and adjusts the speed of motor rounds per minute (RPM) to a pump. Significant power consumption savings can be achieved when using a VFD / VSD Inverter Constant Pressure Booster Pump Manager.

A variable frequency drive (VFD) / variable speed drive (VSD) Inverter Constant Pressure Booster Pump Manager is a system to control the rotational speed of an alternating current (AC) electric motor. It controls the frequency of the electrical power supplied to the motor. A variable frequency drive (VFD) / variable speed drive (VSD) Inverter Constant Pressure Booster Pump Manager is a specific type of adjustable-speed drive. Variable frequency drives (VFD) / variable speed drives (VSD) are also known as adjustable frequency drives (AFD), AC drives, or inverter drives.

A variable frequency drive (VFD) / variable speed drive (VSD) Inverter Constant Pressure Pump Manager includes a primary electrical circuit converting the alternating current (AC) into a direct current (DC), then converting it back into an alternating current (AC) with the required frequency. Internal energy loss in variable frequency drive (VFD) / variable speed drive (VSD) Inverter Constant Pressure Booster Pump Manager is rated around 3.5%

Reasons for using variable frequency drives (VFD) / variable speed drives (VSD) Inverter Constant Pressure Booster Pump Managers can both be related to the functionality of the application and for saving energy. It helps water pump to match either to the demand of volume or pressure. The pump adjusts its revolutions to a given set point via a regulating loop. Adjusting the flow or pressure to the actual demand can reduce power consumption.

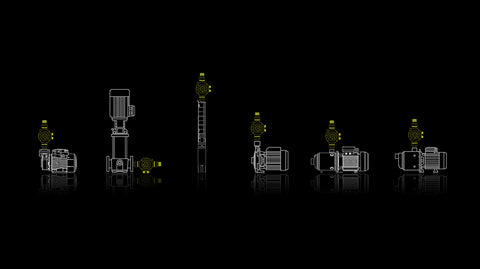

Variable frequency drives (VFD) / variable speed drives (VSD) Inverter Constant Pressure Pump Managers are widely used on various types of water pump such as vertical and horizontal multistage pumps, end suction pumps, vortex pumps, in-line pumps, jet pumps, deep well submersible borehole pump, and many more.

Reference source:

https://www.grundfos.com/service-support/encyclopedia-search/variable-frequencydrive.html

2. Why do we need VFD / VSD Constant Pressure Booster Pump Inverter?

Except for controlling the speed & torque of water pump motors, variable frequency drives (VFD) / variable speed drives (VSD) Inverter Constant Pressure Booster Pump Managers can also help users to:

- Enjoy constant water pressure

- Reduce pump operating noise

- Reduce energy costs

- Adjust pressure setting

- Extend pump lifetime

- Reduce the size requirement of pressure tanks

- Lower maintenance costs and shorter downtime

- Be Eco-friendly & reduce carbon footprint

- Reduce motor harmonics

- Stabilize current demand

- Lower power demand on soft startup

- Adjust torque limits

Reference source:

https://www.edcscotland.co.uk/pages/what-is-a-vsd

Click here to learn about a Faster + Easier + Silent Constant Pressure Solution

3. What is the difference between VFD and VSD?

There is no difference between VSD and VFD in terms of what they are designed to do. There might be some differences based on specific internal components/construction and how they achieve the goals.

- Variable Frequency Drives (VFD): are drives work on changing the frequency of motors; they can be used with AC motors only.

- Variable Speed Drives (VSD): are drives work on changing the speed of motors by varying the voltage supplied to them; they can be used with both AC motors and DC motors.

Reference source:

http://www.gohz.com/difference-between-vsd-vfd-asd-afd

Click here to learn about a Faster + Easier + Silent Constant Pressure Solution

4. What benefits VFD / VSD Constant Pressure Booster Pump Inverter can contribute to improve peoples’ life?

- Enjoy constant water pressure - The most comfortable water shower experience

- Reduce pump operating noise - Good night sleep and better life

- Energy-saving - Lower electricity bill

- Protections for water pump - Pump lifetime extending and cost-saving

- Reduce the size requirement of pressure tanks – Space-saving

- Lower maintenance costs and shorter downtime - Trouble-free water supply

- Be Eco-friendly & reduce carbon footprint

- Lower power demand on soft startup - Lower electricity bill

- Adjust pressure setting - Customized user experience

5. What are the 10 Tips to choose a good VFD / VSD Constant Pressure Booster Pump Inverter?

- Easy assembling with many types of water pump

- Easy installation with pipeline and electricity supply

- The final VFD / VSD inverter Constant Pressure Booster Pump system is space-saving

- Provide real constant water pressure

- Energy-saving for lower electricity bill

- Reduce pump operating noise

- Enhance pump performance

- All-Around protections for water pump

- Clear signal and info display

- Trouble-free maintenance and service

6. What are the 4 major benefits of using VFD / VSD Constant Pressure Booster Pump Inverter?

- Energy-saving

- Constant water pressure providing

- Pump operating noise reducing

- Water pump protecting

7. How does VFD / VSD Constant Pressure Booster Pump Inverter save energy?

Most motors are designed to rotate at a set speed based on the number of magnetic poles built into them and the supply voltage and frequency applied. They cannot alter their speed. Even for fixed speed systems, it can be difficult to find a motor that rotates at the correct speed for its designated application. Therefore, variable frequency drives (VFD) / variable speed drives (VSD) Inverter Constant Pressure Booster Pump Managers are often required.

Variable frequency drives (VFD) / variable speed drives (VSD) Inverter Constant Pressure Booster Pump Managers provide effective speed control of AC motors by manipulating voltage and frequency. Controlling the speed of a motor provides users with improved process control, reduced wear on machines, increased power factor, and large energy savings.

Variable torque load applications like water pumps have torque requirements that increase in proportion to the square of the speed and reach 100% torque just below rated speed

The most significant energy savings can be achieved in applications with a variable torque load. The cube law relationship between speed and power means that reducing a pump’s speed in a variable torque load application by 20% can achieve energy savings of 50%. Therefore, for most motion control applications, reducing motor speed is often the easiest way to get large energy savings.

Reference Source:

https://acim.nidec.com/drives/control-techniques/downloads/how-drives-save-energy

8. How does VFD / VSD Constant Pressure Booster Pump Inverter provide Constant water pressure?

In VFD / VSD Inverter Water Pump System, constant pressure water supply refers to the control mode of the VFD / VSD Inverter Constant Pressure Booster Pump Manager which controls the outlet pressure within the setting value by detecting the pipe and network pressure when the water amount in the pipe and network changes.

Usually, when using a normal water pump, its rated flow is bigger than the actual flow, and the flow varies a lot when in use, for example, in buildings water supply, the water consumption between day and night varies a lot, valve regulation mode is commonly used. Even the method is simple; however, it is regulated by increasing resistance manually which results in a lot of waste in electricity and high maintenance required.

Variable frequency drives (VFD) / variable speed drives (VSD) Inverter Constant Pressure Booster Pump Manager adjust the RPM (Revolution Per Minute) of the motor, based on the measure of the current pressure, to perform the automatic constant pressure water supply for saving energy and providing enjoyable water shower experience.

Reference source:

http://www.acdrive-china.com/applications/vfd-for-constant-pressure-water-supply.htm

9. How does VFD / VSD Inverter Constant Pressure Booster Pump Inverter reduce pump operating noise?

Operating the motor at reduced speed is self-explanatory; cooling air speed and friction are reduced, resulting in less noise created. That said, a given motor may experience increased vibration at characteristic frequencies, which can increase noise to a level greater than that produced at base (i.e. rated) speed. Most Variable frequency drives (VFD) / variable speed drives (VSD) Inverter Constant Pressure Pump Manager can be user-programmed to “jump” those frequencies, thereby avoiding the increased vibration. Of course, this assumes that the process can accept not being driven at those speeds.

Reference source:

https://joliettech.com/blog/variable-frequency-drives-vfds-and-motor-noise/

10. How does VFD / VSD Constant Pressure Booster Pump Inverter protect water pump?

Variable frequency drives (VFD) / variable speed drives (VSD) Inverter Constant Pressure Booster Pump Manager have a built-in circuit breaker that shuts down the motor if the amps get too high for the speed at which the motor is being run. This provides excellent (the best we know of) electrical protection for a motor and the machine it is driving.

It is best to have a Variable frequency drives (VFD) / variable speed drives (VSD) Inverter Constant Pressure Booster Pump Manager that is rated for more horsepower than the motor being driven. This gives more flexibility. However, where electrical overload protection is deemed important, the rating of the actual motor being driven should be loaded into the VFD.

Basically, with a Variable frequency drives (VFD) / variable speed drives (VSD) Inverter Constant Pressure Booster Pump Manager set below 60 Hz, the motor drops maximum horsepower output and instead holds constant torque. Above 60 Hz, the horsepower is limited to the motor nameplate maximum, which means there is a reduction in torque. Some Variable frequency drives (VFD) / variable speed drives (VSD) Inverter Constant Pressure Booster Pump Manager can be set for overload trip on either amps or torque; set it on torque for the best overload protection.

Moreover, with advanced written-in detection logic, a Variable frequency drives (VFD) / variable speed drives (VSD) Inverter Constant Pressure Booster Pump Manager could have All-Around protection as below:

- Dry running protection

- Over and low voltage protection

(Acceptable voltage range from 180V to 265V)

- Over current protection

- Over pressure protection

- Excess temperature protection

- Anti-freezing protection

- Blocked rotor protection

- Leakage warning

Reference source:

https://vincentcorp.com/content/inverter-vfds-dummies/

11. How can VFD / VSD Constant Pressure Booster Pump Inverter enhance water pump performance?

Occasionally we are asked the question about the ability to over-speed motors of water pumps using variable frequency drives (VFD) / variable speed drives (VSD) Inverter Constant Pressure Booster Pump Manager. This question usually comes up when there are capacity issues with a mechanical system and the water pump motor is being relied upon to compensate.

In general, the answer to the question is yes – a motor can be run at higher than its nameplate speed. However, there is a trade-off between operating at higher speeds and the resulting torque (rotational force) capability of the motor. Typically, in most common commercial applications with a constant supply voltage such as 220/240vac the relationship between torque and speed is such that the torque is reduced as the motor speed is increased. There is a direct relationship between speed and electrical AC operating frequency. For example, 0 Hz is equal to 0 rpm and 60 Hz is equal to full speed. Hence, 120 Hz would be the equivalent of double speed.

Rules of thumb- a 3600 rpm motor can be run safely up to about 75 Hz (or 25% above its rated speed).

The real limiting factors for over-speeding a motor are not so much electrical as they are mechanical. Bearing wear and rotational instability resulting from changes in mechanical balancing requirements at speeds above the nominal can lead to motor failure and/or unacceptable vibrations when operating a motor continuously at higher than its rated top speed.

The golden rule to remember is that it is critical to confer with the motor manufacturer before attempting to over-speed any motor.

Reference source:

12. How can it be easier to assemble a VFD / VSD Inverter Constant Pressure Booster Pump system?

Normally, it is quite time consuming and need some technical skill to assemble a VFD / VSD Inverter single Pump system. You will need to put together a water pump with many components such as VFD / VSD Inverter, control box, bottom plate, 5-way connector, pressure sensor, pressure tank, pressure gauge, and check valve.

However, there is a new type of All-In-One & In-Line VFD / VSD Inverter Constant Pressure Booster Pump Manager which makes assembling a VFD / VSD Inverter single Pump system very easy and time-saving. An All-In-One & In-Line VFD / VSD Inverter Constant Pressure Pump Manager is a very compact device that is highly integrated with VFD inverter, pump protector, pressure sensor, flow switch, check valve, pressure tank, union pipe connectors, and cable with plug. To assemble a VFD / VSD Inverter single Pump system, all you need to do is to connect a water pump and an All-In-One & In-Line VFD / VSD Inverter Constant Pressure Booster Pump Manager with its union pipe connector and cable. That’s it! Very easy!

13. How can VFD / VSD Inverter Constant Pressure Booster Pump system be more compact and space-saving?

Generally speaking, a VFD / VSD Inverter single Pump system includes many components such as a water pump, a VFD / VSD Inverter, a control box, a bottom plate, a 5-way connector, a pressure sensor, a pressure tank, a pressure gauge, and a check valve. Therefore, the size of the final product is quite big and space-taking.

Nevertheless, there is a new type of All-In-One & In-Line VFD / VSD Inverter Constant Pressure Booster Pump Manager which can make a VFD / VSD Inverter single Pump system very space-saving. An All-In-One & In-Line VFD / VSD Inverter Constant Pressure Pump Manager is a very compact device which is highly integrated with VFD inverter, pump protector, pressure sensor, flow switch, check valve, pressure tank, union pipe connectors, and cable with plug. To assemble a VFD / VSD Inverter single Pump system, all you need to do is to connect a water pump and an All-In-One & In-Line VFD / VSD Inverter Constant Pressure Booster Pump Manager with its union pipe connector and cable, and it will be very compact and space-saving.

14. How to install VFD / VSD Inverter Constant Pressure Booster Pump?

Frankly speaking, it is not difficult to install a pre-packaged VFD / VSD Inverter Constant Pressure Booster Pump system. All you need to do is to find the right location (well-drained, enough space, easy to connect with water supply pipeline and electricity), use the right tools (screwdriver, wrench, tape seal, pipe fitting, multimeter…), and connect the pump system with the pipeline and electricity. After installation is done, check the pump to see if it turn on and off according to the water usage and make sure there is no water leakage.

However, it would be much more difficult to install a non-pre-packaged VFD / VSD Inverter Constant Pressure Booster Pump system. You will need to find the right components such as control box, bottom plate, 5-way connector, pressure sensor, pressure tank, pressure gauge, and check valve to equip with the water pump and the VFD / VSD Inverter and then put them all together. It is very time-consuming and need some technical skill to complete assembling a VFD / VSD Inverter Constant Pressure Booster Pump system. Once the assembling is done, then you can do the installation.

15. How to maintenance and service for VFD / VSD Constant Pressure Booster Pump Inverter?

It's easier than you might think, but it's something you shouldn't take for granted. By integrating some simple, logical steps into your preventive maintenance program, you can ensure your drives provide years of trouble-free service.

A variable frequency drive (VFD) / variable speed drive (VSD) Inverter Constant Pressure Booster Pump Manager requires the same safety and equipment precautions applied to computers and power supplies because of its similarity to both: Keep it clean, keep it dry, and keep the connections tight.

Keep it clean. Dust on an electronic device can cause malfunction or even failure by absorbing moisture. Discharging compressed air into the variable frequency drive (VFD) / variable speed drive (VSD) Inverter Constant Pressure Booster Pump Manager is a viable option in some environments, but typical plant air contains oil and water. Oil-free, dry air requires a specialized, dedicated, and expensive air supply — and you still run the risk of generating static charges.

Keep it dry. Damages can happen to a control board periodically subjected to a moist environment. Make sure your variable frequency drive (VFD) / variable speed drive (VSD) Inverter Constant Pressure Booster Pump Manager is installed in a clean, dry area of a mechanical room. Variable frequency drive (VFD) / variable speed drive (VSD) Inverter Constant Pressure Booster Pump Manager seldom offer condensation protection today. If you operate the VFD all day, every day, the normal radiant heat from the heat sink should prevent condensation. Unless the unit is in continuous operation, use a thermostatically controlled space heater if you place it where condensation is likely.

Keep connections tight. This may seem obvious, but checking connections is a step many people miss or do incorrectly — and the requirement applies even in clean rooms. Heat cycles, mechanical vibration, and standard PM practices can lead to substandard connections. Also, re-torque screws and excessive tightening can ruin connections. Bad connections eventually lead to arcing. Arcing at the variable frequency drive (VFD) / variable speed drive (VSD) Inverter Constant Pressure Booster Pump Manager input could result in nuisance overvoltage faults, clearing of input fuses, or damage to protective components. Arcing at the variable frequency drive (VFD) / variable speed drive (VSD) Inverter Constant Pressure Booster Pump Manager output could result in over-current faults or even damage to the power components. Loose wiring connections can cause erratic operation. For example, a loose speed reference wire can cause the drive speed to fluctuate, resulting in scrap, machine damage, or injury.

You wouldn't place your laptop outside, on the roof of a building, or in direct sunlight without proper protection. A variable frequency drive (VFD) / variable speed drive (VSD) Inverter Constant Pressure Booster Pump Manager needs the same consideration.

Reference source:

https://www.ecmweb.com/content/tips-more-effective-vfd-maintenance

16. What are the 8 major protections for water pump a good VFD / VSD Constant Pressure Booster Pump Inverter can do?

- Dry running protection

- Over and low voltage protection

- Over current protection

- Over pressure protection

- Excess temperature protection

- Anti-freezing protection

- Blocked rotor protection

- Leakage warning

17. Why dry running protection is important for VFD / VSD Constant Pressure Booster Pump Inverter?

Dry Pump Protection should be integrated into a variable frequency drive (VFD) / variable speed drive (VSD) Inverter Constant Pressure Pump Manager, relate to situations where the pump runs without enough water supply – for example, when the city water supply is cut off. In this situation, the drive sets off an alarm, shuts off the pump, or performs another pre-programmed action, in order to stop the pump from dry-running and prevent damaging the bearing or even the motor.

18. Why over and low voltage protection is important for VFD / VSD Constant Pressure Booster Pump Inverter?

In some countries or areas, the electricity supply is not very stable. In those areas, during the period of electricity peak usage, the voltage might be much lower than what water pumps or VFD / VSD Inverter Constant Pressure Booster Pump Managers can handle. On the other hand, when the total electricity usage is low in those areas, the voltage might be much higher than water pumps or VFD / VSD Inverter Constant Pressure Booster Pump Managers can handle. Moreover, both over and low voltage electricity supply would damage water pumps and VFD / VSD Inverter Constant Pressure Booster Pump Managers. Therefore, it is critical for VFD / VSD Inverter Constant Pressure Booster Pump Manager to have over and low voltage protection.

Click here to learn about a Faster + Easier + Silent Constant Pressure Solution

19. Why over current protection is important for VFD / VSD Constant Pressure Booster Pump Inverter?

Without proper current protection, the motor of a water pump might be damaged or even be burned because the electric current is higher than its rated handling ability.

Variable frequency drive (VFD) / variable speed drive (VSD) Inverter Constant Pressure Booster Pump Manager typically provides electronic overload protection for motors via their internal firmware. With proper setup and commissioning of the variable frequency drive (VFD) / variable speed drive (VSD) Inverter Constant Pressure Booster Pump Manager parameters, the motor can be protected from overheating due to excessive load or other conditions that might cause the motor to run above its Full Load Amp rating. When an overload condition is detected it could lead the drive to give a warning or a fault.

Another method for protecting motors would be for the drive to monitor thermostat sensors that are placed in the motor and to use that feedback to warn or fault. The above methods are good for an application with a single motor on a drive, but in cases where multiple motors are connected to a variable frequency drive (VFD) / variable speed drive (VSD) Inverter Constant Pressure Booster Pump Manager, motor overload protection needs to be handled a bit differently. In this case, individual motor overloads are required and if one of the motors is in an overload condition, that motor’s protection device should open a set of contacts that are wired back to a digital input on the drive so it can indicate there is a problem with one of the motors.

Reference source:

Rick Akey, senior application engineer, low-voltage drives groups, at ABB

20. Why excess temperature protection is important for VFD / VSD Constant Pressure Booster Pump Inverter?

Excess temperature protection is important for VFD / VSD Inverter Constant Pressure Booster Pump Manager is because it can protect the parts like impeller, mechanical seal, bearing, motor, and the driver itself from damaging by too high temperature.

There are various types of excess temperature protection for VFD / VSD Inverter Constant Pressure Booster Pump Managers. One of them is preventing IGBT from overheat and not to damage the drive. Another is thermal protection which prevents the motor from burning.

As for In-Line water-cooled type VFD / VSD Inverter Constant Pressure Booster Pump Manager, there is another excess temperature protection to make sure the drive does not operate under higher water temperature than the max. setting point in order to protect the dive from damaging.

21. Why anti-freezing protection is important for VFD / VSD Constant Pressure Booster Pump Inverter?

In many countries, during wintertime, the ambient temperature will go below 2 degrees C, and the water will turn into ice and might damage the pump end, piping, and the in-line type VFD / VSD Inverter Constant Pressure Booster Pump Manager. With the anti-freezing protection function of VFD / VSD Inverter Constant Pressure Booster Pump Managers, the device will force the pump to operate when the ambient temperature is below the set point to prevent water from becoming ice and cause the damage.

22. Why locked rotor protection function is important for VFD / VSD Constant Pressure Booster Pump Inverter?

When a rotor is locked and still try to start operating, the amperage of the motor will rise dramatically. If there is no protection, the motor will be damaged or even be burned. VFD / VSD Inverter Constant Pressure Booster Pump Manager with blocked rotor protection would detect the amperage of a motor during operation. If the amperage is higher than normal, the VFD / VSD Inverter Constant Pressure Booster Pump Manager will stop the operation and show the warming signal for the technician to check and do the service.

23. Why leakage warning function is important for VFD / VSD Constant Pressure Booster Pump Inverter?

Leakage problems will lead a water pump to run without stopping, run on and off, waste the energy, and might cause the pump to have a shorter lifetime. Moreover, if the leakage problem is more serious, it might cause the flooding damage and might ruin the decoration, furniture, and other pieces of equipment.

As a result, it is very important for a VFD / VSD Inverter Constant Pressure Booster Pump Manager to have a warning function when leakage problem happens. When house owners or technicians notice the leakage problem from the warning signal, they can work on solving the problem before any major damage occurs.

Click here to learn about a Faster + Easier + Silent Constant Pressure Solution

24. What information should be shown on the panel of VFD / VSD Constant Pressure Booster Pump Inverter?

There are some information like setting pressure, current pressure, operation status (run, pause, stop), error code(dry running, over voltage, low voltage, over current, over pressure, excess temperature, blocked rotor, leakage) should be shown on the panel of a good VFD / VSD Inverter Constant Pressure Booster Pump Manager for easier service and maintenance.

Click here to learn about a Faster + Easier + Silent Constant Pressure Solution

25. What are the key parts to assemble VFD / VSD Inverter Constant Pressure Booster Pump system?

There are two common types of VFD / VSD Inverter Constant Pressure Booster Pump system. The first type and the most common one includes a water pump, a VFD / VSD Inverter, a 5-ways connector, a pressure sensor, a pressure tank, , a control box, and a system base plate. The second common type has almost all the same parts as the first type except the control box, and system base plate. It uses a piggy bag type of VFD / VSD inverter which can be directly attached to the top of the junction box of a water pump.

However, there is a new type of VFD / VSD Inverter Constant Pressure Booster Pump system which uses All-In-One & In-Line VFD / VSD Inverter Constant Pressure Pump Manager and doesn’t need extra 5-ways connector, pressure sensor, pressure tank, control box, and system base plate. All it needs is to connect this special device and the water pump with its standard union connector and electric cable. The process of the assembling can be done within 10 minutes which would save tremendous time and cost for technicians or installers.

Click here to learn about a Faster + Easier + Silent Constant Pressure Solution

26. What does a VFD / VSD inverter do for Constant Pressure Booster Pump?

- Run at variable speed based on actual water usage

- Reduce pump operating noise

- Reduce energy costs

- Adjust pressure setting

- Extend pump lifetime

- Reduce the size requirement of pressure tanks

- Lower maintenance costs and shorter downtime

- Reduce motor harmonics

- Stabilize current demand

- Lower power demand on soft startup

- Adjust torque limits

Reference source:

https://www.edcscotland.co.uk/pages/what-is-a-vsd

27. What does a pressure sensor do for VFD / VSD Inverter Constant Pressure Booster Pump?

A variable frequency drive (VFD) / variable speed drive (VSD) Inverter Constant Pressure Booster Pump needs a pressure sensor to be mounted on the outlet to measure the operating pressure and help the pump to determine to run or stop, and the running speed. The VFD / VSD Inverter Constant Pressure Booster Pump Manager will be set to keep the water pressure of the pump constant, no matter what flow is produced from the pump.

28. What does the check valve do for VFD / VSD Inverter Constant Pressure Booster Pump?

There are two places that need to have a check valve for a VFD / VSD Inverter Constant Pressure Booster Pump. The first one is before the inlet of the pump which could prevent water back flowing from the pump to the water resource and make sure the pump to have suction lift capability. The second one is after the outlet of a VFD / VSD Inverter Constant Pressure Booster Pump which could prevent water back flowing from discharge port to the pump, water hammer to damage the pump, and to maintain the pressure in the pressure tank of a VFD / VSD Inverter Constant Pressure Pump.

Click here to learn about a Faster + Easier + Silent Constant Pressure Solution

29. What does pressure tank do for VFD / VSD Inverter Constant Pressure Booster Pump?

There are two reasons why a VFD / VSD Inverter Constant Pressure Booster Pump need to be equipped with a pressure tank. The first one is for water hammer buffering to protect the pump and piping from water hammer damage. The other one is to maintain the system pressure to prevent water pump from short cycling. However, since most of the VFD / VSD Inverter Constant Pressure Booster Pump have soft start and soft stop function, the size of the pressure tank does not need to be big.

30. Why most of the VFD / VSD Inverter Constant Pressure Booster Pumps are expensive?

The reasons why most of the VFD / VSD Inverter Constant Pressure Booster Pumps are expensive are as below:

- VFD / VSD Inverter cost: Most of the VFD / VSD Inverter Constant Pressure Booster Pumps are equipped with general inverters which can also be used for fans, compressors, and many types of machinery. Most of the time, the parts and functions of a general inverters are not just for water pumps and might be wasted. Therefore, the cost of general inverter is too expensive for VFD / VSD Inverter Constant Pressure Booster Pump.

- Other parts: It needs a 5-ways connector, a pressure tank, a pressure sensor, a pressure gauge, a control box, and a base plate to put together a standard VFD / VSD Inverter Constant Pressure Booster Pump. To purchase all those parts are quite expensive.

- Labor cost: It takes a long time to put together a water pump, a VFD / VSD Inverter, a 5-ways connector, a pressure tank, a pressure sensor, a pressure gauge, a control box, and a base plate to become a VFD / VSD Inverter Constant Pressure Booster Pump. As a result, the labor cost would be also expensive.

Click here to learn about a Faster + Easier + Silent Constant Pressure Solution

31. How many types of VFD / VSD Constant Pressure Booster Pump Inverter are there in the market?

The types of VFD / VSD Inverter Constant Pressure Booster Pump Manager can be distinguished by where it is assembled with a pump system as below:

- In a separated control box:

- General type VFD / VSD Inverter

- Dedicated type VFD / VSD Pump Inverter

- Piggyback on the motor:

- Piggyback type VFD / VSD Pump Inverter

- Directly connected with the pump outlet:

- In-Line type VFD / VSD Inverter Constant Pressure Booster Pump Manager

- All-In-One& In-Line type VFD / VSD Inverter Constant Pressure Pump Manager

32. What is an All-In-One & In-line VFD / VSD Constant Pressure Booster Pump Inverter?

All-In-One & In-line VFD / VSD Inverter Constant Pressure Booster Pump Manager is a compact device that is highly integrated with VFD inverter, pump protector, pressure sensor, flow switch, check valve, pressure tank, union pipe connectors, and cable with plug. Moreover, it can be directly connected with the pump outlet. As a result, it is a much better solution for space-saving and easy assembling compared to other types of VFD / VSD pump inverter.

33. What are the advantages of All-In-One & In-Line VFD / VSD Constant Pressure Booster Pump Inverter?

- Space-saving.

A VFD / VSD Inverter Constant Pressure Booster Pump system equipped with an All-In-One VFD / VSD Inverter Constant Pressure Booster Pump Manager doesn’t need a separated Manager box to be attached on a big pump base plate. Therefore, it is a very space-saving design.

- Easy assembling for even DIYers.

Contractors or DIYers can buy an All-In-One VFD / VSD Inverter Constant Pressure Booster Pump Manager and easily connect it with their existing water pump or a newly purchased one. All they need to do is to connect the device and the water pump with a very user-friendly union connecter and electricity port.

- Fast and cost-saving on installation

Once a VFD / VSD Inverter Constant Pressure Booster Pump system is assembled, all you need to do is connect the system with water piping and plug in the electrical plug. The installation is very fast and you don’t need to prepare a lot of extra accessories such as pressure tank, 5-way connecter, control box, pump base plate, pressure sensor, and pressure gauge to do the installation.

Click here to learn about a Faster + Easier + Silent Constant Pressure Solution

34. How easy it is to assemble All-In-One & In-Line VFD / VSD Constant Pressure Booster Pump Inverter with a water pump?

It is super easy to assemble an All-In-One & In-Line VFD / VSD Inverter Constant Pressure Booster Pump Manager with a water pump. All you need to do is to connect a water pump and an All-In-One & In-Line VFD / VSD Inverter Constant Pressure Booster Pump Manager with its standard union connecter and electricity cable. The assembling can easily be completed in 10 minutes or less.

35. What does flow switch do for VFD / VSD Inverter Constant Pressure Booster Pump?

Normally, a traditional VFD / VSD Inverter Constant Pressure Booster Pump only count on the pressure sensor to determine whether to start or stop. However, with only a pressure sensor, a VFD / VSD Inverter Constant Pressure Booster Pump might have problem to stop running when the water usage is small and be slowly shouted down. In this case, a VFD / VSD Inverter Constant Pressure Booster Pump might still running at very low speed but cannot fully stop. Moreover, if the water usage is as low as 3 or 5 liters per minute, a VFD / VSD Inverter Constant Pressure Booster Pump with only pressure sensors might not run stably.

However, a VFD / VSD Inverter Constant Pressure Booster Pump with a pressure sensor and also a flow switch can fully stop running when water usage is small and be slowly shouted down. Moreover, even the water usage is as low as 3 liters per minute, a VFD / VSD Inverter Constant Pressure Booster Pump equipped with a flow switch can still run very stably.

36. What does union pipe connectors do for VFD / VSD Inverter Constant Pressure Booster Pump?

A VFD / VSD Inverter Constant Pressure Booster Pump with union pipe connectors can be easily and quickly connected to the water piping. Moreover, when maintaining and servicing is needed, it will be very convenient that a VFD / VSD Inverter Constant Pressure Booster Pump with union pipe connectors to be disconnected from the water piping.

37. What types of water pump can work with All-In-One & In-Line VFD / VSD Constant Pressure Booster Pump Inverter?

There are many types of water pump such as horizontal and vertical multistage centrifugal pump, single-stage centrifugal pump, peripheral pump, jet pump, vortex pump, in-line pump, deep well borehole pump, and many more can work with an All-In-One & In-Line VFD / VSD Inverter Constant Pressure Booster Pump Manager and easily become a VFD / VSD Inverter Constant Pressure Booster Pump system to provide constant water pressure, to save energy, and to reduce operating noise.

38. What mistakes do people make when choosing VFD / VSD Constant Pressure Booster Pump Inverter?

People might choose the wrong VFD / VSD Inverter Constant Pressure Booster Pump Manager which have bad features as below:

- Difficult to assemble with water pump

- The size of the final VFD / VSD Inverter Constant Pressure Pump system is too big for the space

- The VFD / VSD Inverter Constant Pressure Booster Pump Manager cannot work suitably with the water pump.

- Difficult installation and pipe work

- Provide not constant and not stable water pressure

- Low energy saving rate

- Cannot reduce pump operating noise

- Not enough protection for water pump

- Not clear indication for setting pressure, current pressure, and various error status

- Not easy to set parameters

Click here to learn about a Faster + Easier + Silent Constant Pressure Solution

39. What mistakes do people make when install VFD / VSD Inverter Constant Pressure Booster Pump?

- Pick the wrong size of water pump, VFD / VSD Inverter, or both

- Install in the wrong place

- Not using union or flange connection with piping

- Not using a check valve

- Not using or using the wrong size of pressure tank

- Not protecting the VFD / VSD Inverter from rain, dust, and heat

- Pump base/frame not grouted & bolted

- Not setting the proper parameters of the VFD / VSD Inverter

Click here to learn about a Faster + Easier + Silent Constant Pressure Solution

40. What are the 10 things to avoid when selecting a VFD / VSD Inverter Constant Pressure Booster Pump?

- Do not select the one which is not easy to be assembled with the water pump you choose

- Do not select the one which is not easy to be installed with pipeline and electricity supply

- Do not select the one with too big size and cannot fit with the space

- Do not select the one doesn’t provide real constant water pressure

- Do not select the one doesn’t save energy

- Do not select the one cannot reduce pump operating noise

- Do not select the one cannot enhance pump performance

- Do not select the one doesn’t provide enough protection for water pump

- Do not select the one doesn’t have clear indication for necessary operation info and status

- Do not select the one which is difficult to do the maintenance and service for

- Do not select the one which is difficult to set parameters

Click here to learn about a Faster + Easier + Silent Constant Pressure Solution

41. What are the shocking truths of lousy VFD / VSD Inverter Constant Pressure Booster Pump?

- Lousy VFD / VSD Inverter Constant Pressure Booster Pump do not really save energy

- Lousy VFD / VSD Inverter Constant Pressure Booster Pump cause operating noise

- Lousy VFD / VSD Inverter Constant Pressure Booster Pump does not have enough protecting function to have a longer service life

- Lousy VFD / VSD Inverter Constant Pressure Booster Pump do not provide real constant water pressure

Click here to learn about a Faster + Easier + Silent Constant Pressure Solution

42. Why not many people use VFD / VSD Inverter Constant Pressure Booster Pump?

- Most of the VFD / VSD Inverter Constant Pressure Booster Pump are very expensive

- Most of the VFD / VSD Inverter Constant Pressure Booster Pump does not have good quality and cannot last long

- Most of the VFD / VSD Inverter Constant Pressure Booster Pump does not save energy

- Most of the VFD / VSD Inverter Constant Pressure Booster Pump is not user-friendly and can only be installed and set up by very professional technician

- Most of the VFD / VSD Inverter Constant Pressure Booster Pump is not easy to do the maintenance and service for

Click here to learn about a Faster + Easier + Silent Constant Pressure Solution